ZF Success Story:

Complementing R&D with the Power of Innovation

149+

NEW IDEAS VALIDATED

14+

IDEAS FUNDED

+3601

COMMUNITY OF INNOVATORS

About ZF

ZF Friedrichshafen has been in the automotive systems business for over 100 years. Today, ZF is a global technology company supplying systems for passenger cars, commercial vehicles, and industrial technology, enabling the next generation of mobility. With more than 150.000 people in almost every region of the world, including Europe, North and South America, Africa, and Asia.

ZF has consistently pursued initiatives to solidify their position as a leading innovator in their industry. Their Innovation Factory was established with the objective of navigating and promptly responding to upcoming trends in the automotive sector.

The Challenge

Maintaining Customer-Focused Innovation in a Disrupted Industry

The automotive industry is experiencing significant changes driven by various trends, including automation, digitalization, and electromobility. In response to societal demands for greater efficiency, resource conservation, and enhanced climate protection, the industry is undergoing profound shifts to adapt and evolve. For the team at ZF’s Innovation Factory, change is thus not an option, but instead, a survival skill.

With a customer base that is becoming more distributed, the production process as well as the design process are changing, requiring engineers to adopt a broader view of product requirements to ensure they meet the end-customer’s needs. Notably, a significant portion of the workforce comprises engineers, making it crucial for them to take a step back and approach problems from the customer’s standpoint.

Developing a Company-Wide Innovation Culture

The team at ZF also came to the realization that to sustain a robust culture of innovation, they had to revamp their existing innovation process, as well as unlock a company-wide innovation culture that would engage people and allow them to live their passion by working on ideas they believe in. Seeing that innovation needs the right culture to thrive, the team needed a tool that would allow them to empower their employees holistically and, in a bottom-up way.

The Solution

Launching an Employee-Driven Innovation Program to Develop Customer-Centered Products

To combat these challenges, ZF launched an employee-driven intrapreneurship program to support innovation. The program enables all employees - regardless of title or location - to develop ideas using a gamified methodology, with no prior innovation experience required. In the starting phase, participants receive a budget of €1,000, 20% of their work hours, expert support, and the KICKBOOK guide to validate their idea. Promising ideas then progress through to next phase (the pilot phase) and eventually the third phase (implementation). Based on a stage-gate approach, each phase helps to de-risk concepts through real feedback and validation.

.webp?width=1100&height=734&name=Untitled%20design%20(7).webp)

ZF’s goal was to shift engineers from purely technical problem-solving to addressing real customer pain points. The pilot began in the US and Germany, with 15 innovators per region, supported by coaching cohorts and internal campaigns like newsletters and Demo Days.

As Manuel Leichtle of ZF put it, “The program helps us balance technical excellence with true customer need. Bottom-up innovation gives every idea a chance—because understanding the customer is no longer optional, it’s essential for survival.”

The Results

The program has so far yielded enormous successes at ZF. Employees have been very enthusiastic about submitting ideas and developing them into pitches that can attract an internal sponsor. After one year of running the program, 40 new ideas were validated, across 9 different divisions and an innovation community of over 3601 employees was formed. Almost two years later, and the number of the validated ideas has grown to over 149, with 14 ideas progressing to the pilot phase.

According to Manuel, employee feedback on the program has been highly positive. “The main tone is that it’s very cool that you’re offering something different, something that opens my mind.”

High-impact Project

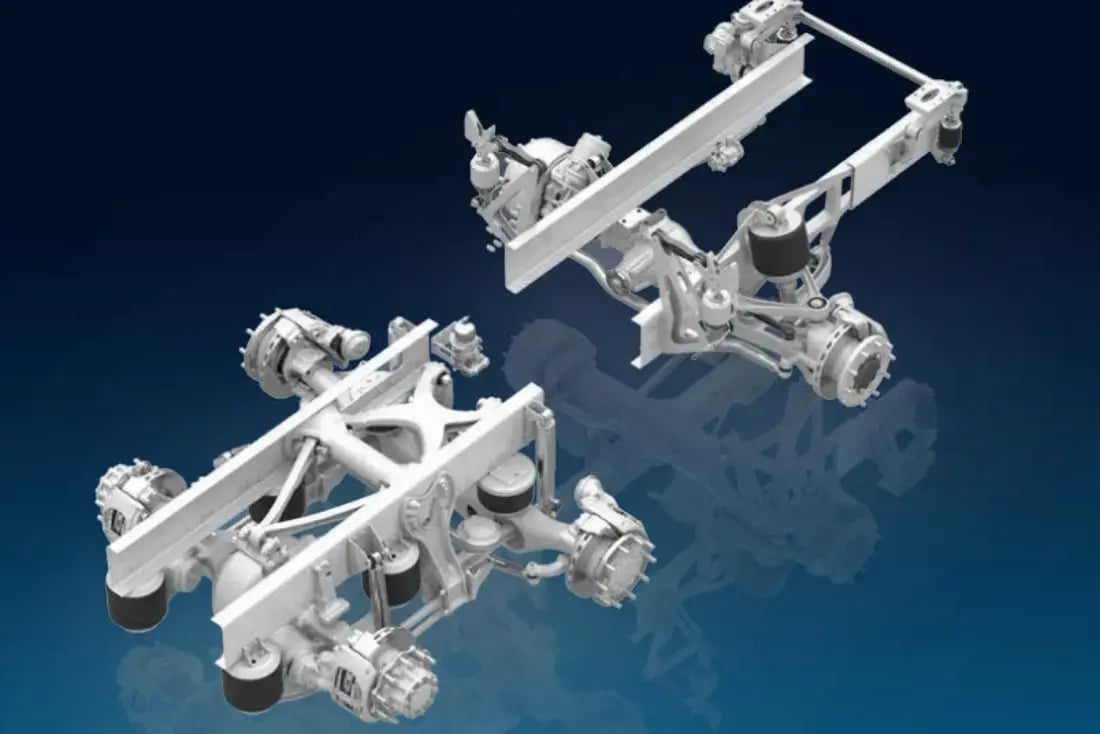

Chassis in the Loop

Creating a revolutionary new test environment for a more efficient and less expensive chassis testing process.

Chassis in the Loop was developed by André Laatz from ZF. This idea involves a combination of a standard component test bench (hardware) and a simulation (software). The solution delivers first-rate test results while eliminating the traditional costs linked to testing, such as building prototypes, shipping vehicles, or maintaining test tracks.